Kwi-metallurgy, zombini ubushushu obugqithisileyo kunye nokutshisa ngokugqithisileyo ngamagama aqhelekileyo anxulumene nonyango lwe-thermal yesinyithi, ngakumbi kwiinkqubo ezifana nokubumba, ukuphosa, kunye nonyango lobushushu. Nangona zihlala zibhidekile, ezi ziganeko zibhekisa kumanqanaba ahlukeneyo omonakalo wobushushu kwaye zineziphumo ezahlukileyo kwiintsimbi. Eli nqaku libonelela ngombono wokutshisa kunye nokutshisa, kulandelwa ukuphononongwa kweeyantlukwano zabo eziphambili.

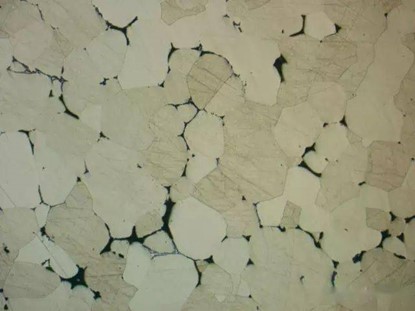

Ukutshisa ngokugqithisileyo:Ukushisa okugqithisileyo kubhekiselele kwimeko apho isinyithi sifudunyezwa ngaphaya kobushushu obucetyiswayo, okukhokelela kulwakhiwo lweenkozo ezirhabaxa. Kwi-carbon steel (zombini i-hypoeutectoid kunye ne-hypereutectoid), ukufudumala ngokugqithiseleyo kubonakala ngokubunjwa kwezakhiwo ze-Widmanstätten. Kwizixhobo zensimbi kunye ne-high-alloy steels, ukugqithisa kubonakalisa njenge-angular shape ye-primary carbides. Kwezinye iintsimbi ze-alloy, ukufudumeza ngokugqithiseleyo kunokubangela imvula yezinto kunye nemida yeenkozo. Enye yezinto eziphambili ezixhalabisayo ngokugqithiswa kobushushu kukuba iinkozo ezirhabaxa ezibangelwayo zinokubeka esichengeni iipropathi zoomatshini zentsimbi, ziyenze ibe ncinci kwaye ibe brittle. Nangona kunjalo, kwiimeko ezininzi, umonakalo obangelwa ukushisa ngokugqithiseleyo unokuncitshiswa okanye uguqulwe ngonyango olufanelekileyo lobushushu.

Ukutshisa kakhulu:Ukutshisa kakhulu yimeko enzima ngakumbi xa kuthelekiswa nokushisa. Kwenzeka xa isinyithi sibonakaliswe kumaqondo obushushu angaphaya kwendawo yawo yokunyibilika, nto leyo ebangela ukuba impahla yonakale ngaphaya kokulungiswa. Kwiintsimbi ezitshiswe kakhulu, iintanda zinokubumba ngoxinzelelo oluncinci ngexesha lokuguqulwa. Ngokomzekelo, xa isinyithi esitshisiweyo sibethelwa ngexesha lokuphazamiseka, siqhekeka ngokulula, kwaye ngexesha lokwandisa, ukuqhekeka okunqamlezayo kunokuvela. Iindawo ezitshiswe ngokugqithisileyo zohlulwe ngeenkozo ezirhabaxa kakhulu, kwaye iindawo eziqhekekileyo zihlala zibonisa umbala ongwevu-blue okhanyayo. Kwii-alloys ze-aluminiyam, ukutshisa ngokugqithiseleyo kubangela ukuba umphezulu ube mnyama, ngokuphindaphindiweyo ukwenza umbala omnyama okanye omnyama ongwevu kunye nenkangeleko edibeneyo, ephawulweyo. Ukwandiswa okuphezulu kuveza ukuba ukutshisa kakhulu kudla ngokunxulunyaniswa ne-oxidation kunye nokunyibilika ecaleni kwemida yeenkozo. Kwiimeko ezinzima, ulwelo lunokuthi lwenzeke kwimida yeenkozo, okubangela ukuba izinto eziphathekayo zonakaliswe ngokungenakulungiseka.

Umahluko oPhambili:Umahluko ophambili phakathi kobushushu obugqithisileyo kunye nokutshisa okugqithisileyo kuxhomekeke kubunzima kunye nokuhlala ixesha elide komonakalo. Ukushisa okugqithisileyo kubangela ukuba iinkozo zibe rhabaxa, kodwa isinyithi sinokusoloko sibuyiselwa kwimeko yaso yangaphambili ngeendlela ezifanelekileyo zonyango lobushushu. Umonakalo ngokuqhelekileyo unqunyelwe kwiinguqu kwi-microstructure kwaye awukhokeli ekungaphumeleli kwentlekele ngokukhawuleza ngaphandle kokuba izinto eziphathekayo ziphantsi koxinzelelo olukhulu.

Ngakolunye uhlangothi, ukutshisa ngokugqithiseleyo kubonisa imeko ebaluleke kakhulu apho izinto zenza umonakalo ongenakuguqulwa. Ukunyibilika okanye i-oxidation yemida yeenkozo kuthetha ukuba isakhiwo sangaphakathi sesinyithi siphazamiseka ngaphaya kokulungiswa. Ukutshisa okugqithisileyo kubangela ukuba brittleness kunye nokuqhekeka, kwaye akukho xabiso lonyango olulandelayo lobushushu linokubuyisela iimpawu zemishini.

Isishwankathelo, ukufudumala kunye nokushisa okugqithiseleyo zombini zihambelana nokufudumeza okugqithisileyo, kodwa ziyahluka kwimpembelelo yazo kwiintsimbi. Ukushisa ngokugqithiseleyo kunokutshintshwa rhoqo, ngelixa ukutshisa ngokugqithiseleyo kubangela umonakalo ongenakuguqulwa, okukhokelela ekulahlekeni okukhulu kwengqibelelo yezinto eziphathekayo. Ukuqonda lo mahluko kubalulekile ekuqinisekiseni ukuba ulawulo olufanelekileyo lweqondo lokushisa lugcinwa ngexesha leenkqubo ze-metallurgical, ukuthintela ukusilela kwezinto kunye nokuqinisekisa ixesha elide lamacandelo esinyithi.

Ixesha lokuposa: Oct-08-2024