Kwinkqubo yokubumba, ukuphazamisa kubhekiselele ekuguqulweni kwendawo yokusebenza ukwandisa ububanzi bayo ngokucinezela ubude bayo. Iparameter ebalulekileyo ekuphazamiseni yiUmlinganiselo wobude ukuya kububanzi (H/D ratio), edlala indima ephambili ekumiseleni umgangatho wemveliso yokugqibela kunye nokuba nokwenzeka kwenkqubo. Umlinganiselo wobude ukuya ku-diameter usetyenziselwa ukuqinisekisa ukuba i-deformation ihlala ilawulwa kwaye ifana, ukukhusela imiba efana ne-buckling, i-crack, okanye ukungaphumeleli kwezinto.

Yintoni iRetiyo yoMphakamo ukuya kuMdayamitha?

Umlinganiselo wobude ukuya kwi-diameter (H / D ratio) ngumlinganiselo phakathi kobude (okanye ubude) be-workpiece kunye nobukhulu bayo ngaphambi kokubunjwa. Lo mlinganiselo unceda ukucacisa ukuba ingakanani imathiriyeli enokonakala ngenxa yenkqubo ephazamisayo. Ngokuqhelekileyo, okukhona umlinganiselo omncinci, kokukhona inkqubo yokuphazamiseka iba nokwenzeka ngakumbi ngenxa yokuba izinto ezimfutshane, ezityebileyo zinokumelana namandla amakhulu oxinzelelo ngaphandle kokubopha okanye ukuphuhlisa iziphene.

Ngokomzekelo, umlinganiselo ophantsi we-H / D, onjenge-1.5: 1 okanye ngaphantsi, ubonisa i-stubby workpiece, enokusingatha imithwalo ephezulu yoxinzelelo ngaphandle kweengozi ezinkulu zokungazinzi. Kwelinye icala, umlinganiselo ophezulu, onje nge-3:1 okanye ngaphezulu, unokufuna ukuqwalaselwa ngocoselelo ngakumbi, njengoko i-workpiece iya ithandeka ngakumbi kwiziphene.

Ungasibona njani esona Singqinisiso seH/D?

Umlinganiselo ofanelekileyo we-H/D uxhomekeke kwizinto ezininzi, kubandakanywa iipropati zezinto eziphathekayo, ubushushu bezinto eziphathekayo ngexesha lokubumba, kunye neqondo lokuguqulwa okufunekayo. Nanga awona manyathelo aphambili okumisela owona mlinganiselo we-H/D wokuphazamisa:

- Iimpahla zeMathiriyeli: Izinto ezahlukeneyo zibonisa amandla ahlukeneyo oxinzelelo kunye ne-ductility. Izinto ezithambileyo, ezifana ne-aluminium, ziyakwazi ukunyamezela ukuguqulwa okungaphezulu ngaphandle kokuqhekeka, ngelixa izinto ezinzima ezifana ne-carbon steel high-carbon zingadinga umlinganiselo ophantsi we-H / D ukuphepha uxinzelelo olugqithiseleyo. Uxinzelelo lokuhamba kwezinto, oko kukuthi, uxinzelelo olufunekayo ukuqhubeka nokuguqula izinto zeplastiki, kufuneka zithathelwe ingqalelo.

- Iimeko Zobushushu: I-Hot forging yenziwa ngokuqhelekileyo kumaqondo obushushu aphucula i-ductility yezinto kunye nokunciphisa amandla afunekayo. Amaqondo obushushu aphezulu avumela ukuguqulwa okukhulu, okuvumela umlinganiselo omkhulu wobude ukuya kububanzi. Ukubumba okubandayo, umlinganiselo we-H / D kufuneka ugcinwe umncinci ngenxa yokwanda komngcipheko wokuqina komsebenzi kunye nokuqhekeka.

- Inqanaba loTshintsho: Ubungakanani bokuguqulwa obufunekayo ngomnye umba obalulekileyo. Ukuba ukuncipha okubonakalayo kobude kuyadingeka, ukuqala ngomlinganiselo ophantsi we-H / D kunenzuzo ukuqinisekisa ukuba i-workpiece inokungena kuxinzelelo olufunekayo ngaphandle kweziphene.

- Ukuphepha Iziphene: Xa umisela umlinganiselo we-H / D, kubalulekile ukuphepha iziphene ezifana ne-buckling, eyenzeka xa izinto ezigoqayo okanye imibimbi ngexesha loxinzelelo. Ukuze ugweme ukubopha, umgaqo oqhelekileyo wesithupha kukusebenzisa umlinganiselo wokuqala we-H / D ongaphantsi kwe-2: 1 kwi-forging jikelele. Ukongeza, ukuthambisa kunye noyilo olufanelekileyo lokufa lubalulekile ukunciphisa ingxabano kunye nokuqinisekisa ukuguqulwa okufanayo.

Umzekelo Oluncedo

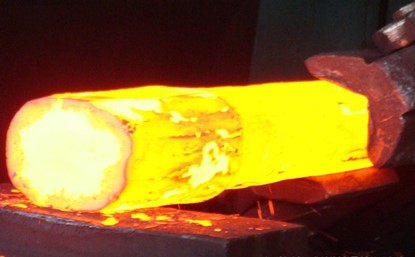

Cinga ngemeko yokuphazamisa i-cylindrical billet yensimbi. Ukuba ukuphakama kokuqala kwe-billet yi-200 mm kunye nobubanzi be-100 mm, umlinganiselo we-H / D uya kuba ngu-2: 1. Ukuba i-material ithambile, kwaye i-forging eshushu iyasetyenziswa, lo mlinganiselo unokwamkeleka. Nangona kunjalo, ukuba i-forging ebandayo isetyenzisiweyo, ukunciphisa ukuphakama ukunciphisa umlinganiselo we-H / D kunokuba yimfuneko ukunqanda ukubethelwa okanye ukuqhekeka ngexesha lokuphazamiseka.

Ukuqukumbela

Umlinganiselo wobude ukuya kwi-diameter ekuphazamisekeni yinkalo esisiseko yokubumba emisela impumelelo yenkqubo. Ngokuphonononga ngononophelo iipropathi zemathiriyeli, ubushushu, kunye neemfuno zoguquko, umlinganiselo ofanelekileyo unokusekwa, uqinisekisa ukuveliswa kwezinto ezibunjiweyo ezikumgangatho ophezulu, ezingenasiphako.

Ixesha lokuposa: Sep-18-2024