Umxholo wekhabhoni kwintsimbi yenye yezona zinto zibalulekileyo ezichaphazela i-weldability yezinto zokwakha. Insimbi, indibaniselwano yentsimbi kunye nekhabhoni, ingaba namanqanaba ahlukeneyo ekhabhoni, echaphazela ngokuthe ngqo iipropathi zayo zemishini, kubandakanya amandla, ukuqina, kunye ne-ductility. Ukwenzela i-welded forgings, ukuqonda ubudlelwane phakathi komxholo wekhabhoni kunye nokusebenza kwe-welding kubalulekile ukuqinisekisa ukuthembeka kunye nomgangatho wamalungu adibeneyo.

Iintsimbi ezinekhabhoni ephantsi, ezidla ngokuqulatha ngaphantsi kwe-0.30% yekhabhoni, zezona zinto zikwazi ukuwelda. Ezi ntsimbi zibonakalisa i-ductility elungileyo kunye ne-malleability, izenza zilungele uluhlu olubanzi lwezicelo ze-welding. Umxholo wekhabhoni ophantsi unciphisa umngcipheko wokuqhekeka kwindawo echaphazelekayo ukushisa (HAZ) ngexesha nangemva kwe-welding. Oku kungenxa yokuba amanqanaba asezantsi ekhabhoni abangela ukuqina okuphantsi, oku kuthetha ukuba izinto azifane zikwazi ukwenza i-brittle microstructures efana ne-martensite, enokuba yingxaki kwiindawo ezidityanisiweyo. Ngaloo ndlela, i-forgings enomxholo ophantsi wekhabhoni ivame ukuba nemibandela embalwa enxulumene nokuqhekeka okanye ukuphazamiseka ngexesha leenkqubo ze-welding.

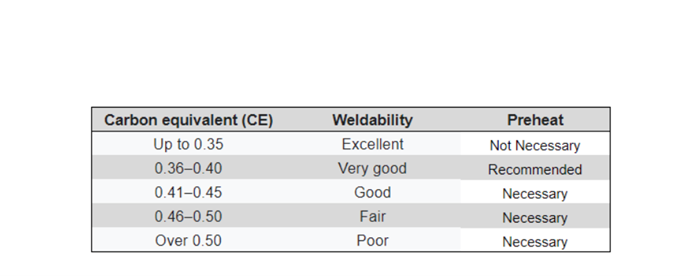

Ngokwahlukileyo koko, njengoko umxholo wekhabhoni usanda, i-weldability yensimbi iyancipha. Iintsimbi zekhabhoni ephakathi, kunye nomxholo wekhabhoni ophakathi kwe-0.30% kunye ne-0.60%, zinika amandla aphezulu kunye nobunzima xa kuthelekiswa neentsimbi eziphantsi kwekhabhoni kodwa ziza kunye neengozi ezongeziweyo ngexesha le-welding. Umxholo wekhabhoni ophezulu ukhokelela ekubeni lukhuni ngakumbi, okwandisa amathuba okwenza izakhiwo ze-martensitic kwi-HAZ. Ezi microstructures zinzima kwaye zine-brittle, ziphakamisa amathuba okuqhekeka, ngakumbi phantsi koxinzelelo okanye impembelelo. Ukhathalelo olukhethekileyo, olufana nokushisa kwangaphambili kunye nonyango lobushushu lwasemva kwe-weld, luhlala lufuneka xa u-welding medium-carbon steel forgings ukuthintela le miba.

Iintsimbi eziphezulu zekhabhoni, eziqulethe ngaphezu kwe-0.60% yekhabhoni, zibeka imingeni enkulu yokudibanisa. Umxholo wekhabhoni ophezulu unyusa kakhulu ubulukhuni bentsimbi kunye nokuqina, okwenza kube lula ukuqhekeka ngexesha lenkqubo ye-welding. Kwezinye iimeko, iintsimbi ezinekhabhoni ephezulu zinokufuna iindlela ezikhethekileyo zokuwelda okanye zingakulungelanga ukuwelda kwaphela ngaphandle kohlengahlengiso olukhulu kwinkqubo. Ukufudumeza, ukulawulwa kobushushu obuphakathi, kunye nonyango lobushushu lwasemva kwe-weld lubalulekile ukunqanda ukungaphumeleli kwe-brittle kwi-high-carbon steel forgings.

Isishwankathelo, umxholo wekhabhoni wensimbi udlala indima ebalulekileyo ekumiseleni impumelelo ye-welding kumacandelo akhiweyo. Iintsimbi ezinekhabhoni ephantsi zezona zikwazi ukuwelda, ngelixa iintsimbi eziphakathi kunye neziphezulu zekhabhoni zifuna ukulawulwa ngononophelo ngakumbi kwiiparamitha ze-welding ukuthintela iziphene ezinjengokuqhekeka. Ukuqonda umxholo wekhabhoni kunye nokukhetha iinkqubo ezifanelekileyo ze-welding ziyimfuneko ekuqinisekiseni ukuqina kunye nokusebenza kwee-welded forgings kwizicelo ezahlukeneyo zoshishino.

Ixesha lokuposa: Oct-16-2024