Ukusebenza kwe-forging kubalulekile kwizicelo ezahlukeneyo zemizi-mveliso, ukusuka kumacandelo eemoto ukuya kwiindawo ze-aerospace. Ukongezwa kwezinto ezahlukeneyo ze-alloy kunokuchaphazela kakhulu iipropathi zezixhobo ezibunjiweyo, ukomeleza amandla azo, ukuqina, kunye nokuchasana nezinto ezisingqongileyo. Eli nqaku liphonononga ezinye zezinto eziphambili ze-alloying kunye nendlela ezichaphazela ngayo ukusebenza kwe-forgings.

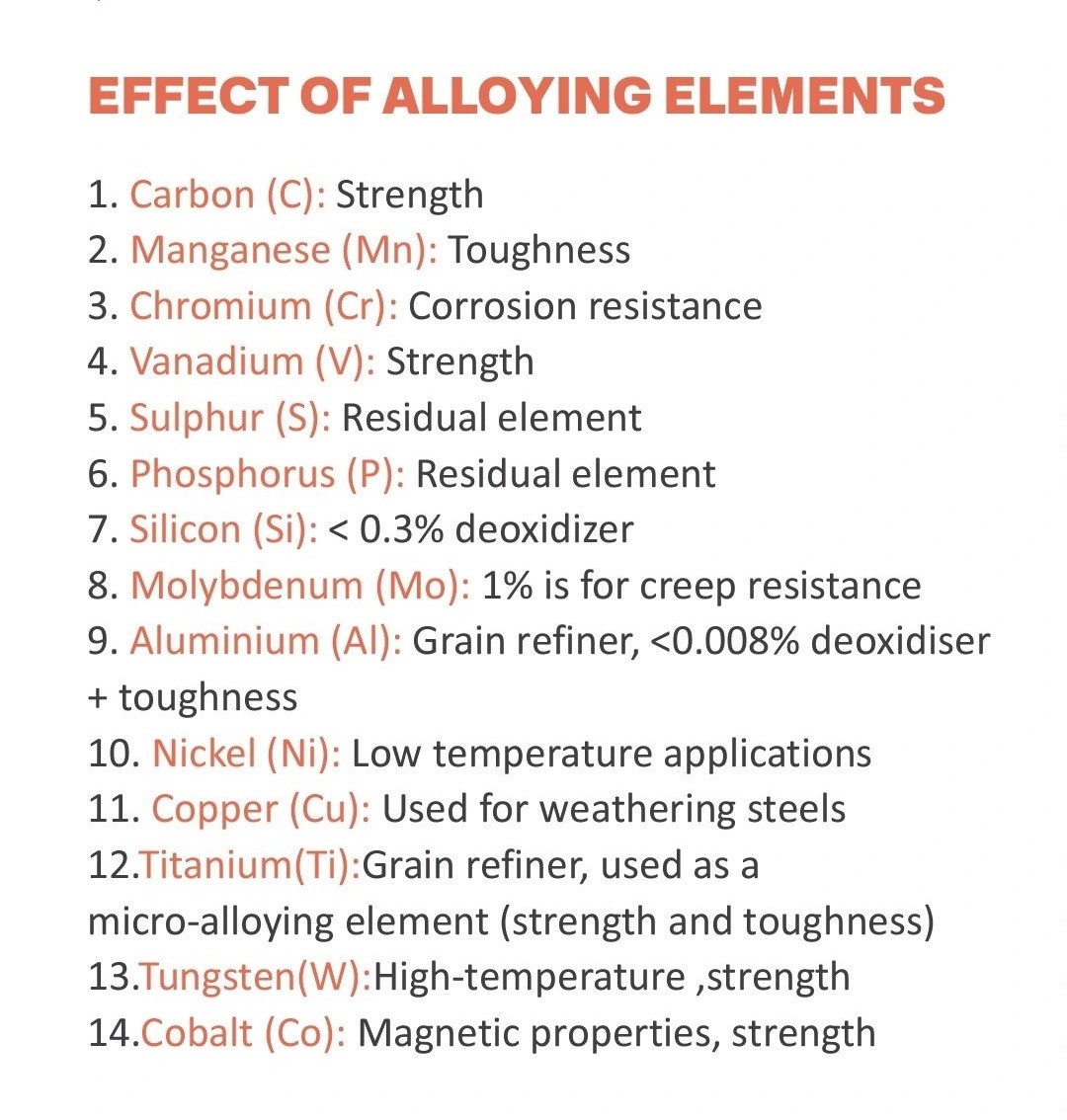

Izinto ezingundoqo zokuHlanganisa kunye neziphumo zazo

Ikhabhoni (C):

Ikhabhoni yenye yezona zinto zibaluleke kakhulu kwi-alloying element kwintsimbi. Ichaphazela ngokuthe ngqo ubunzima kunye namandla ezinto eziphathekayo. Umxholo wekhabhoni ophezulu wonyusa ubulukhuni kunye namandla okuqina okubumba, okwenza ukuba ilungele izicelo ezifuna ukuxhathisa okuphezulu, njengezixhobo zokusika kunye neengxenye zeemoto. Nangona kunjalo, i-carbon eninzi kakhulu inokwenza ukuba izinto zibe brittle, ukunciphisa ukuxhathisa kwayo.

I-Chromium (Cr):

I-Chromium yaziwa ngokukwazi kwayo ukuphucula ukuxhathisa umhlwa kunye nokuqina. Yenza umaleko wokwenziwa kwechromium oxide kumphezulu, ikhusela i-forging kwi-oxidation kunye nokubola. Oku kwenza ukuba iintsimbi ezinealloyidi yechromium zilungele ukusetyenziswa kwiindawo ezirhabaxa, ezinje ngemizi-mveliso yaselwandle neyemichiza. Ukongeza, i-chromium yongeza ukuqina kwentsimbi, ukuyivumela ukuba ifikelele amandla aphezulu kunye nokuqina emva konyango lobushushu.

I-Nickel (Ni):

I-nickel yongezwa kwi-forgings ukuphucula ukuqina kunye ne-ductility, ngakumbi kumaqondo aphantsi. Ikwaphucula ukuxhathisa kwemathiriyeli kwi-corrosion kunye ne-oxidation. Iintsimbi ezine-nickel-alloyed ziqhele ukusetyenziswa kwi-aerospace kunye ne-oyile kunye nemizi-mveliso yegesi, apho zombini amandla aphezulu kunye nokuchasana neendawo ezinzima zifuneka. Ubukho be-nickel buphinde buzinzise isigaba se-austenitic, okwenza intsimbi ingabi-magnetic kunye nokuphucula ukusebenza kwayo.

Iimpembelelo eziDityanisiweyo kunye nezicelo zoShishino

Ukudityaniswa kwezi kunye nezinye izinto ezidibeneyo, ezifana ne-molybdenum (Mo), i-vanadium (V), kunye ne-manganese (Mn), inokuvelisa izinto ezineempawu ezilungiselelwe izicelo ezithile. Umzekelo, i-molybdenum inyusa amandla obushushu obuphezulu kunye nokumelana nokunyuka kwentsimbi, iyenza ilungele iiblade ze-injini kunye neenqanawa zoxinzelelo. I-Vanadium ilungisa ubume bengqolowa, iphucula amandla kunye nokuqina kokubumba. I-Manganese isebenza njenge-deoxidizer kwaye iphucula ukuqina kunye nokuqina kwamandla ezinto eziphathekayo.

Kwishishini leemoto, iifogi ezidityaniswe ngokulungeleleneyo zekhabhoni, ichromium, kunye nemanganese zisetyenziselwa ukuvelisa amandla aphezulu, izinto ezikwaziyo ukunxitywa njenge crankshafts kunye negiya. Kwicandelo le-aerospace, i-nickel kunye ne-titanium alloys zibalulekile ekwenzeni iindawo ezikhaphukhaphu kodwa ezomeleleyo ezikwaziyo ukumelana nobushushu obugqithisileyo kunye noxinzelelo.

Ukuqukumbela

Ukusebenza kwe-forging kuphenjelelwa kakhulu kukongezwa kwezinto ezixutywayo, nganye inegalelo leempawu ezithile eziphucula ukusebenza ngokupheleleyo kwemathiriyeli. Ukuqonda indima yezinto ezinje ngekhabhoni, ichromium, kunye nenickel inceda i-metallurgists kunye neenjineli ziyile iifogi ezihlangabezana neemfuno ezibangwayo zezicelo ezahlukeneyo zemizi-mveliso. Ngokukhetha ngononophelo kunye nokudibanisa ezi zinto, abavelisi banokuvelisa i-forgings ekumgangatho ophezulu ngamandla amakhulu, ukuqina, kunye nokuchasana nezinto ezisingqongileyo, ukuqinisekisa ukuthembeka kunye nokuphila ixesha elide kwizicelo zabo.

Ixesha lokuposa: Jul-30-2024